| Because of its corrosion resistance, zinc is often plated to other metals in a process called galvanization; galvanized roofing shown here. |

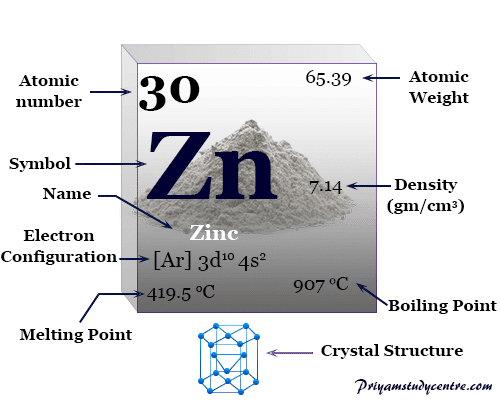

- What is ZINC?Zinc is a chemical element with symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. In some respects zinc.

- Zinc,( chemical symbol Zn,) has an atomic number of 30, which means it has 30 protons in its nucleus. In any neutral atom, the number of electrons is equal to the number of protons.

- Zinc (atomic number 30, symbol Z) is a chemical element and transition metal which is commonly found in the Earth's crust. This is a lustrous, reactive metal with a bluish-white color. It was discovered in 1746 by Andreas Marggraf, a German chemist who is known as a pioneer in the field of analytical chemistry.

Zinc

.jpg/1200px-Na_(Sodium).jpg)

| Atomic Number: | 30 | Atomic Radius: | 139 pm (Van der Waals) |

| Atomic Symbol: | Zn | Melting Point: | 419.5 °C |

| Atomic Weight: | 65.39 | Boiling Point: | 907 °C |

| Electron Configuration: | [Ar]4s23d10 | Oxidation States: | -2, 0, +1, +2 (an amphoteric oxide) |

History

Zinc Zinc is a chemical element with symbol Zn and atomic number 30. Classified as a transition metal, Zinc is a solid at room temperature.

From the German word Zink, of obscure origin. Centuries before zinc was recognized as a distinct element, zinc ores were used for making brass. An alloy containing 87 percent zinc has been found in prehistoric ruins in Transylvania.

Metallic zinc was produced in the 13th century A.D. India by reducing calamine with organic substances such as wool. The metal was rediscovered in Europe by Marggraf in 1746. He demonstrated that zinc could be obtained by reducing calamine with charcoal.

Sources

The principal ores of zinc are sphalerite (sulfide), smithsonite (carbonate), calamine (silicate), and franklinite (zinc, manganese, iron oxide). One method of zinc extraction involves roasting its ores to form the oxide and reducing the oxide with coal or carbon, with subsequent distillation of the metal.

Isotopes

Naturally occurring zinc contains five stable isotopes. Sixteen other unstable isotopes are recognized.

Properties

Zinc is a bluish-white, lustrous metal. It is brittle at ordinary temperatures but malleable at 100 to 150°C. It is a fair conductor of electricity, and burns in air at high red heat with evolution of white clouds of the oxide.

It exhibits superplasticity. Neither zinc nor zirconium is ferromagnetic; but ZrZn2 exhibits ferromagnetism at temperatures below 35°K. It has unusual electrical, thermal, optical, and solid-state properties that have not been fully investigated.

Uses

The metal is employed to form numerous alloys with other metals. Brass, nickel silver, typewriter metal, commercial bronze, spring bronze, German silver, soft solder, and aluminum solder are some of the more important alloys.

Large quantities of zinc are used to produce die castings, which are used extensively by the automotive, electrical, and hardware industries. An alloy called Prestal(R), consisting of 78 percent zinc and 22 percent aluminum, is reported to be almost as strong as steel and as easy to mold as plastic. The alloy said to be so moldable that it can be molded into form using inexpensive ceramics or cement die casts.

Zinc is also used extensively to galvanize other metals such as iron to prevent corrosion. Zinc oxide is a unique and very useful material for modern civilization. It is widely used in the manufacture of paints, rubber products, cosmetics, pharmaceuticals, floor coverings, plastics, printing inks, soap, storage batteries, textiles, electrical equipment, and other products. Lithopone, a mixture of zinc sulfide and barium sulfate, is an important pigment.

Zinc sulfide is used in making luminous dials, X-ray and TV screens, and fluorescent lights.

The chloride and chromate are also important compounds. Zinc is an essential element in the growth of human beings and animals. Tests show that zinc-deficient animals require 50 percent more food to gain the same weight as an animal supplied with sufficient zinc.

Handling

Zinc is not considered to be toxic, but when freshly formed ZnO is inhaled a disorder known as oxide shakes or zinc chills sometimes occurs. Where zinc oxide is encountered, recommendations include providing good ventilation to avoid concentration exceeding 5 mg/m3, (time-weighted over an 8-hour exposure, 40-hour work week).

Our editors will review what you’ve submitted and determine whether to revise the article.

Join Britannica's Publishing Partner Program and our community of experts to gain a global audience for your work!Atom Of Zinc

Zinc (Zn), chemical element, a low-melting metal of Group 12 (IIb, or zinc group) of the periodic table, that is essential to life and is one of the most widely used metals. Zinc is of considerable commercial importance.

| atomic number | 30 |

|---|---|

| atomic weight | 65.39 |

| melting point | 420 °C (788 °F) |

| boiling point | 907 °C (1,665 °F) |

| density | 7.133 grams/cm3 at 25 °C (68 °F) |

| oxidation state | +2 |

| electron configuration | [Ar]3d104s2 |

Occurrence, uses, and properties

A little more abundant than copper, zinc makes up an average of 65 grams (2.3 ounces) of every ton of Earth’s crust. The chief zinc mineral is the sulfidesphalerite (zinc blende), which, together with its oxidation products smithsonite and hemimorphite, constitute nearly all of the world’s zinc ore. Native zinc has been reported from Australia, New Zealand, and the United States, and the leading early 21st-century producers of zinc are China, Australia and Peru. For zinc’s mineralogical properties, seenative element.

Zinc is an essential trace element in the human body, where it is found in high concentration in the red blood cells as an essential part of the enzymecarbonic anhydrase, which promotes many reactions relating to carbon dioxidemetabolism. The zinc present in the pancreas may aid in the storage of insulin. Zinc is a component of some enzymes that digest protein in the gastrointestinal tract. Zinc deficiency in nut-bearing and fruit trees causes such diseases as pecan rosette, little leaf, and mottle leaf. Zinc functions in the hemosycotypsin of snails’ blood to transport oxygen in a way analogous to iron in the hemoglobin of human blood.

Metallic zinc is produced by roasting the sulfide ores and then either leaching the oxidized product in sulfuric acid or smelting it in a blast furnace. Zinc is won from the leach solution by electrolysis or is condensed from the blast furnacegas and then distilled of impurities. For specific information on the mining, recovery, and refining of zinc, seezinc processing.

The major uses of zinc metal are in galvanizing iron and steel against corrosion and in making brasses and alloys for die-casting. Zinc itself forms an impervious coating of its oxide on exposure to the atmosphere, and hence the metal is more resistant to ordinary atmospheres than iron and corrodes at a much lower rate. In addition, because zinc tends to oxidize in preference to iron, some protection is afforded the steel surface even if some of it is exposed through cracks. The zinc coating is formed either by hot-dip galvanizing or electrogalvanizing.

Hot-dip galvanizing is the most common procedure for coating steel with zinc. This may be a batch process known as general galvanizing or a continuous coating of coils of steel strip. In general galvanizing, steel is pickled in acid, treated with fluxing agents, and then dipped in a bath of molten zinc at about 450 °C (840 °F). Layers of iron-zinc alloy are formed on the surface and are topped with an outer layer of zinc. Objects so treated range from small nuts and bolts to steel window frames and large girders used in construction. An ordinary grade of zinc containing up to 1.5 percent lead is normally used in this process.

In electrogalvanizing, zinc is deposited on a steel strop in as many as 20 consecutive electrolytic coating cells. There are several successful cell designs; the simple vertical cell is discussed here to explain the principle. The strip, connected to the negative side of a direct current through large-diameter conductor rolls located above and between two cells, is dipped into a tank of electrolyte by a submerged sink roll. Partially submerged anodes, opposing the strip, are connected to the positive side of the electric current by heavy bus bars. Zinc cations (i.e., positively charged zinc atoms) present in the electrolyte are converted by the current into regular zinc atoms, which deposit on the strip. The bath is supplied with zinc cations either by zinc anodes, which are continuously dissolved by the direct current, or by zinc compounds continuously added to the electrolyte. In the latter case the anodes are made of insoluble materials, such as titanium coated with iridium oxide. The electrolyte is an acidic solution of zinc sulfide or zinc chloride with other bath additions to improve the quality of the coating and the current efficiency. Coating thickness is easier to control than in the hot-dip process because of the good relationship between electrical current and deposited zinc.

Zinc Atomic Number And Mass

The negative electrode (outside can) in one common type of electric dry cell is composed of zinc. Another important series of alloys are those formed by the addition of 4 to 5 percent aluminum to zinc; these have a relatively low melting point but possess good mechanical properties and can be cast under pressure in steel dies. Considerable quantities of zinc in the rolled form are used for roofing, particularly in Europe; small additions of copper and titanium improve creep resistance—i.e., resistance to gradual deformation.

Freshly cast zinc has a bluish silver surface but slowly oxidizes in air to form a grayish protective oxide film. Highly pure zinc (99.99 percent) is ductile; the so-called prime western grade (99.8 percent pure) is brittle when cold but above 100 °C (212 °F) can be rolled into sheets that remain flexible. Zinc crystallizes in the hexagonal close-packed structure. When iron and zinc together are exposed to a corrosive medium, they constitute an electrolytic cell, and the zinc is attacked (oxidized to the Zn2+ ion) preferentially because of its higher electrode potential. This so-called sacrificial protection, coupled with the much greater corrosion resistance of zinc under atmospheric conditions, is the basis for galvanizing.

Natural zinc is a mixture of five stable isotopes: 64Zn (48.6 percent), 66Zn (27.9 percent), 67Zn (4.1 percent), 68Zn (18.8 percent), and 70Zn (0.6 percent).

Atomic Number 30

- key people

- related topics